IoT in manufacturing: A heads-up

Imagine a world where every device in your factory is connected, communicating, and optimizing itself. Where downtime is predicted and prevented, quality is assured in real-time, and decision-making is as efficient as a well-oiled machine. This is not a distant dream, but a reality that’s unfolding as we speak. So, why is IoT in manufacturing gaining traction in 2022 and beyond? Let’s dive in and find out.

Intricacies of IoT

The Internet of Things (IoT) is revolutionizing the manufacturing industry. The ability to connect, communicate with, and remotely manage an incalculable number of networked, automated devices via the Internet is becoming pervasive, from the factory floor to the supply chain to field operations. This connectivity allows for unprecedented levels of automation and efficiency, leading to reduced operational costs, improved product quality, and faster time to market.

Furthermore, the data generated by these connected devices provides valuable insights that can drive strategic decision-making and innovation. As such, the adoption of IoT in manufacturing is not just a trend, but a strategic necessity for manufacturers looking to stay competitive in the digital age.

According to a study, around 35% of manufacturers in the United States collect and use data generated from smart sensors to enhance manufacturing processes. That’s endless data assemblage waiting to be streamlined into effective efficiency enhancing formulae. What an amazing tech, right? But hold your pre-judgements till you hear the flipside.

Challenges of IoT Adoption in Manufacturing and Business

While the benefits of IoT in manufacturing are clear, it’s also important to understand the challenges it brings.

Data Security/Privacy Issues

As IoT systems become more commonplace, each IoT device represents an attack surface that can be an avenue into your data for hackers. Major IIoT adopters believe the concept is increasing the risk of cyberattacks. This is a significant concern as the compromise of a single device can potentially lead to the compromise of the entire network.

Uncertainty in ROI

Implementing IoT requires several investments like hardware expense (sensors, gateways), cloud storage expense, cost of connectivity and administrative labor, etc. Businesses and industries have to consider quick solutions to generate a good ROI. This uncertainty in ROI can be a deterrent for many businesses considering IoT adoption.

Lack of Qualified System

Another challenge is the lack of qualified systems and the unfamiliarity of employees with IoT usage. The system lacks specific skills such as embedded data, electronics, Big Data, and IoT security.

Adoption of IoT – The Zest Way

Despite the numerous challenges put forward, the good outweighs the bad by tonnes. The Internet of Things (IoT) is revolutionizing the world around us, transforming the way we live and work. One company at the forefront of this transformation is ZestIoT, with its innovative solutions like Prediction.

ZestIoT’s Predicton is a powerful tool that harnesses the power of IoT to provide accurate and timely predictions. AI-powered systems transcend mere monitoring, transforming conveyor belt operations with predictive capabilities and actionable insights, paving the way for a new era of optimized material flow.

Imagine a network of high-resolution cameras equipped with the keen eye of artificial intelligence, meticulously scrutinizing every aspect of your conveyor belts. Predicton’s advanced algorithms analyze this real-time data, pinpointing potential issues before they manifest. Misalignment, wear and tear, blockages, and environmental factors are all meticulously assessed, yielding a comprehensive understanding of your belt’s health and performance.

But Predicton doesn’t stop at mere observation. It translates this data into actionable intelligence, empowering you with:

-

Predictive Maintenance:

Schedule interventions before minor issues escalate into costly breakdowns, ensuring uninterrupted operations and extending belt life.

-

Optimized Belt Performance:

Precise data on tension and speed allows for adjustments that maximize efficiency and minimize wear, leading to cost savings and increased productivity.

-

Enhanced Material Handling:

Real-time insights into material flow enable proactive measures to prevent blockages and jams, ensuring smooth movement and product quality.

-

Data-Driven Decision Making:

Predictive reports and real-time alerts provide the foundation for informed strategic choices, fostering continuous improvement and operational excellence.

The Big ‘WHY’

While IoT in manufacturing is gaining traction, it’s important to understand both the benefits and challenges it brings. With the right approach and solutions like ZestIoT’s PREDICTON, businesses can effectively navigate these challenges and harness the power of IoT.

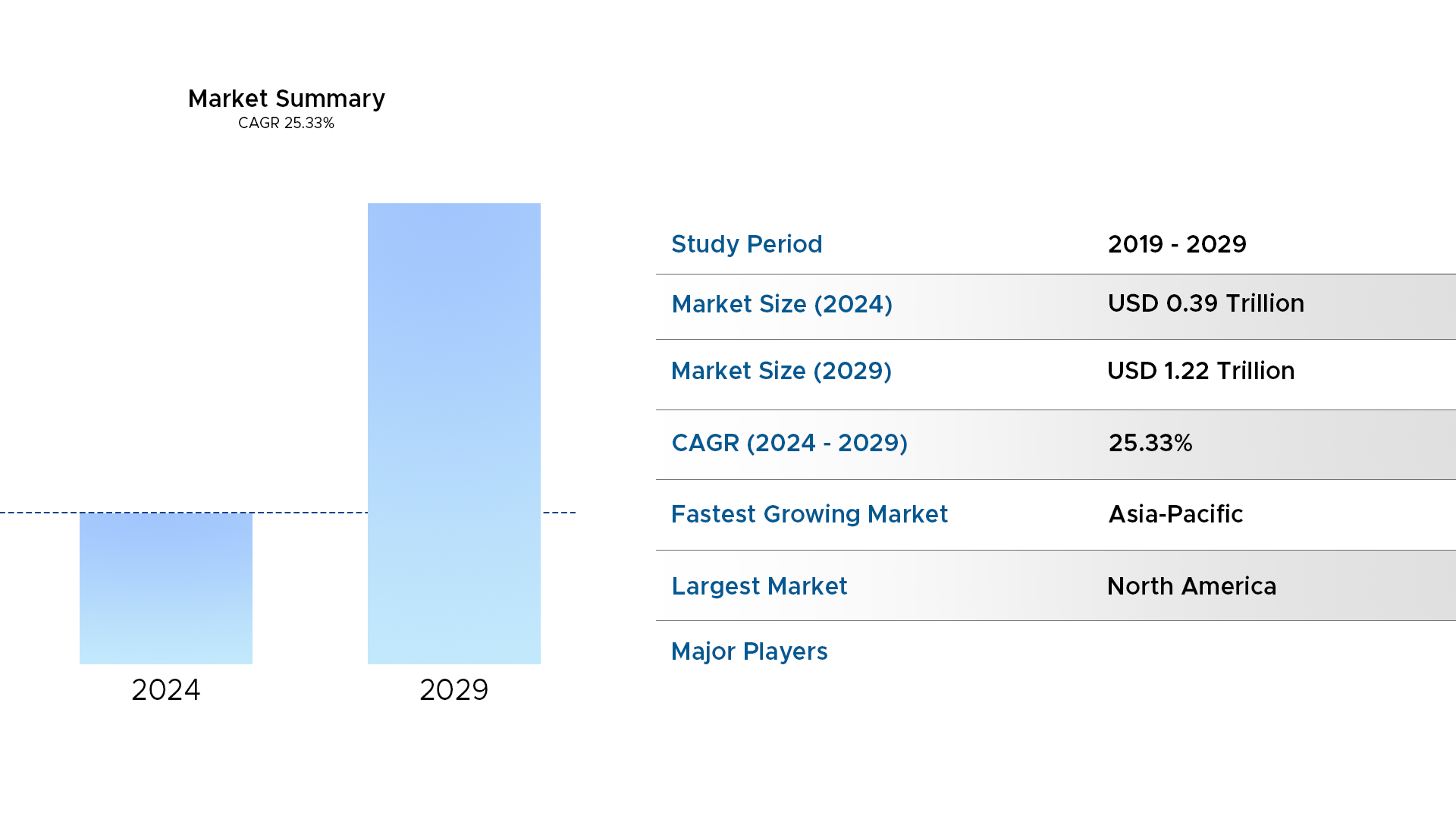

The Internet of Things (IoT) is not just a buzzword in the manufacturing industry – it’s a game-changer. With 91% of enterprises investing in IoT and smart manufacturing, and the global IoT in manufacturing market size expected to grow to USD 53.8 billion by 2025, it’s clear that IoT is here to stay.

The adoption of IoT in manufacturing is not just about keeping up with the latest technology trends. It’s about harnessing the power of data to make smarter decisions, improve efficiency, and ultimately, drive growth. As we move forward, we can expect to see even more innovative uses of IoT in manufacturing, further transforming the industry.

So, whether you’re a small manufacturer looking to improve your operations, or a large corporation seeking to stay competitive in the global market, there’s no better time than now to embrace IoT. The future of manufacturing is here, and it’s powered by IoT.

Recent Comments