Precision AI : Revolutionising F&B Quality with Automated End-of-Line Inspection

A significant step in Manufacturing technology is the use of AI driven EOL (End of Line) inspection that inspect each unit without compromising efficiency (line speeds)

The ZestIoT Machine Vision solution leverages Predicton platform solution to this game,offering automated product inspection, identification, and sorting capabilities tailored specially for pouches and transparent bottles within the F&B industry environment.

Transforming End-of-Line Quality Assurance Through Advanced AI Insights

Defect Detection

Predicton can detect defects, contaminants, functional flaws, and other irregularities in the production line of pouches and transparent bottles.

High-Speed Operation

Visual Appearance Monitoring

Our platform monitors the visual appearance of the pouches and transparent bottles.

Using ZestIOT’s AI models, the system automatically identifies potential defects in the material’s surface and classifies the defects into groups based on similarity in contrast, texture or geometry.

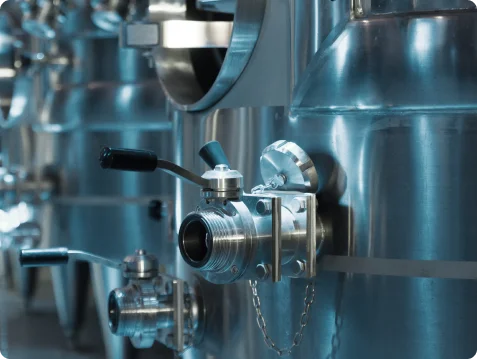

Hardware Components

Predicton inspection systems come equipped with a camera or multiple cameras, and lighting and an industrial grade housing unit.

Interface

Predicton comes with Interactive web based dashboard and interface and generates insights for continuous improvement and creates a base for analytics.

Versatility

Predicton lets you incorporate multiple inspections from captured images or video footage. They can be used to determine the position of an object, ensure package integrity, verify quality standards, identify flaws, count items, check on characteristics specific to a SKU.